-

Code202410-0258

CONTACT

-

Phone: (028) 3726 2168

Email: bht@bht.vn

What is Composite Steel?

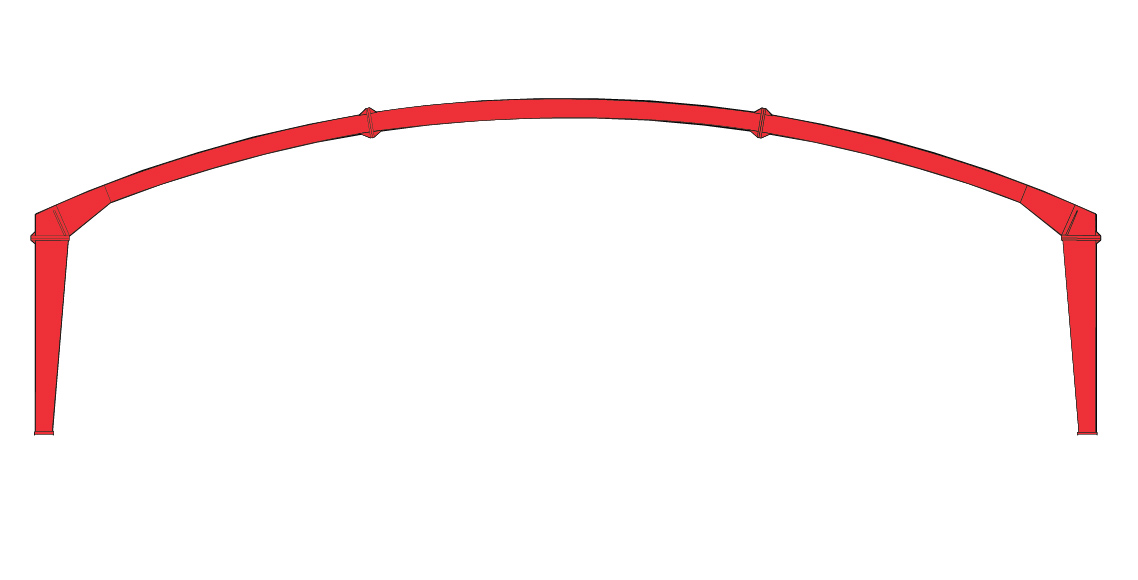

Composite steel or composite-shaped steel refers to steel components with typical shapes such as I-beams, H-beams, etc., made from steel plates. In the process of manufacturing composite steel, steel plates are cut and assembled into steel components according to the dimensions and technical requirements of the project. It is called composite-shaped steel because the product is assembled from steel plates of different sizes using welding machines to create a product with specific dimensions. Almost all sizes of composite-shaped steel products are not available in conventional cast steel shapes.

What are the characteristics of Composite Steel?

Currently, composite steel is mainly composite H-shaped steel and I-shaped composite steel because conventional cast steel shapes have size limitations and insufficient length to meet the technical requirements of large-scale steel structures, such as pre-engineered steel frame buildings or multi-story steel frame buildings. In cases requiring large spans and high load-bearing capacities, composite steel must be used to fully meet the technical requirements set by architects for such projects.

However, composite steel must meet the following technical requirements to be used:

- Load-bearing requirements (TTGH 1)

- Deflection requirements (TTGH 2)

- Economic requirements (the weight of composite steel must be minimized while still meeting the technical standards according to the structural load-bearing drawings)

In practice, increasing the height (h) is very effective in improving the bending capacity and reducing the deflection of beams.

How is Composite Steel Classified?

Composite steel is classified based on cross-sectional configuration:

- I, H Composite Steel: Suitable for columns, roof trusses in factory buildings, and other types of steel frame buildings, as well as load-bearing beams for floors in multi-story steel frame buildings.

- U Composite Steel: Used for wall beams and floor beams when the span is small and the load is light.

Additionally, there are composite steel shapes such as L, V, etc., depending on other technical requirements in the engineering drawings.

Role of Composite Steel

As mentioned above, composite steel plays an extremely important role in construction projects related to steel structures, such as pre-engineered steel frame factories and large-span buildings, where conventional cast steel shapes cannot meet the technical requirements of the projects.