.jpg)

DISTINGUISHING TYPES OF CABLE LADDER AND CABLE TRAY

The cable tray cable ladder system helps protect the safety of cables and construction workers, reduces the risk of scratches and damage to cable sheaths, and does not cause injury to construction workers.

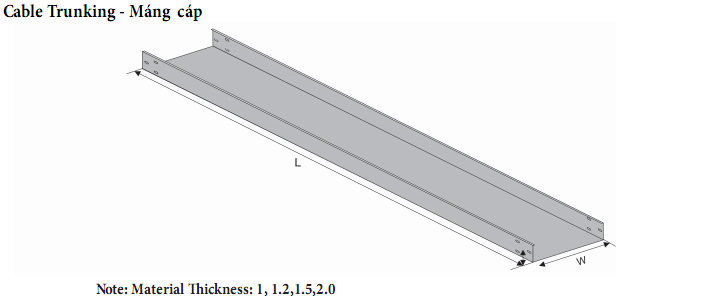

Cable trunking's English name is " cable trunking", which is a system for supporting and installing electrical wires and cables (insulated). The cable trunking system is used to install and protect electrical distribution cables. or communication signal cables in buildings, factories, apartments...

Cable tray systems apply to cable management in commercial and industrial construction, especially useful in the case of changing a wiring system, as new cables can be installed by placing them in the tray cable instead of installing through a pipe.

Materials commonly used for cable trays include: Powder-coated steel, galvanized steel sheet, hot-dip galvanized steel, stainless steel (Inox), aluminum alloy or composite.

Cable tray size:

Popular width: 50 ÷ 600mm

Popular height: 40 ÷ 200mm

Popular length: 2440mm, 2500mm or 3000mm

Common material thickness: 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm and 2.5mm

Popular colors: White, cream, gray, orange or the color of the material

The cable tray system in construction is a system that includes cable trays and cable tray accessories such as cable tray L-shaped redirection, cable tray T-shaped redirection, cable tray support, cable tray connector, cable tray cover and cable tray hanging ti.

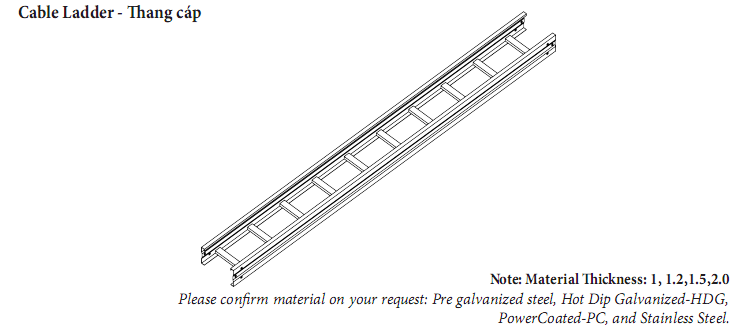

Cable ladder's English name is "cable ladder" or a system for supporting and installing electrical wires and cables (insulated). Cable ladder systems are used in electrical wiring and cable systems in buildings, factories, apartments...

Cable ladder size:

Popular width: 100 ÷ 1000mm

Popular height: 50 ÷ 200mm

Popular length: 2440mm, 2500mm or 3000mm

Common material thickness: 1.0mm, 1.2mm, 1.5mm, 2.0mm and 2.5mm

Popular colors: White, cream, gray, orange or the color of the material

The ladder and cable tray system also includes: horizontal extension, cross extension, T-shaped extension, up, down, left reduction, right reduction, middle reduction and other accessories.

Horizontal trunking is also known as electrical trunking (English name is Flat bend trunking):

- Horizontal contraction (Co L) is used to redirect the trough system in a perpendicular direction on the same plane.

- The cable tray (Fork) is used to divide the trough system into three directions on the same plane.

Ten cable trays are also called crosses

- Ten cable trays (Crossroads) are used to divide the cable tray system into four directions on the same plane

Contraction: English name is Internal bend trunking):

- Shrink up (Shoot Belly, Shrink Trong) is used to redirect the cable tray system perpendicular to the original plane in an upward direction.

Shrinking down is also called Shrinking down the electrical trough (English name is External bend trunking):

- Shrink down (Back Shrink, Outer Shrink) is used to redirect the cable tray system perpendicular to the original plane in a downward direction.

Reducing cable trunking is also known as Reducing electrical trunking (English name is Reducer trunking):

- Reducing cable trays is used to reduce the width or both the height and width of the cable tray system.

BHT Tecnology currently has 8 branches and 5 factories, with continuous production, ensuring quick product supply to meet all customer needs.

Other News

- BHT GROUP CÔNG BỐ QUYẾT ĐỊNH BỔ NHIỆM - PHÓ TỔNG GIÁM ĐỐC KINH DOANH DÂN DỤNG & CÔNG NGHIỆP

- BHT Group tổ chức Hội nghị chiến lược toàn hệ thống: Nâng tầm nội lực – Vững tiến tương lai

- Nâng Tầm Quản Trị KPI Với AI – Bước Tiến Mới Của BHT Group

- THÔNG BÁO LỊCH NGHỈ GIỖ TỔ HÙNG VƯƠNG 2025

- BHT Group HELD THE APPOINTMENT CEREMONY OF SENIOR LEADERS IN THE FIRST QUARTER OF 2025